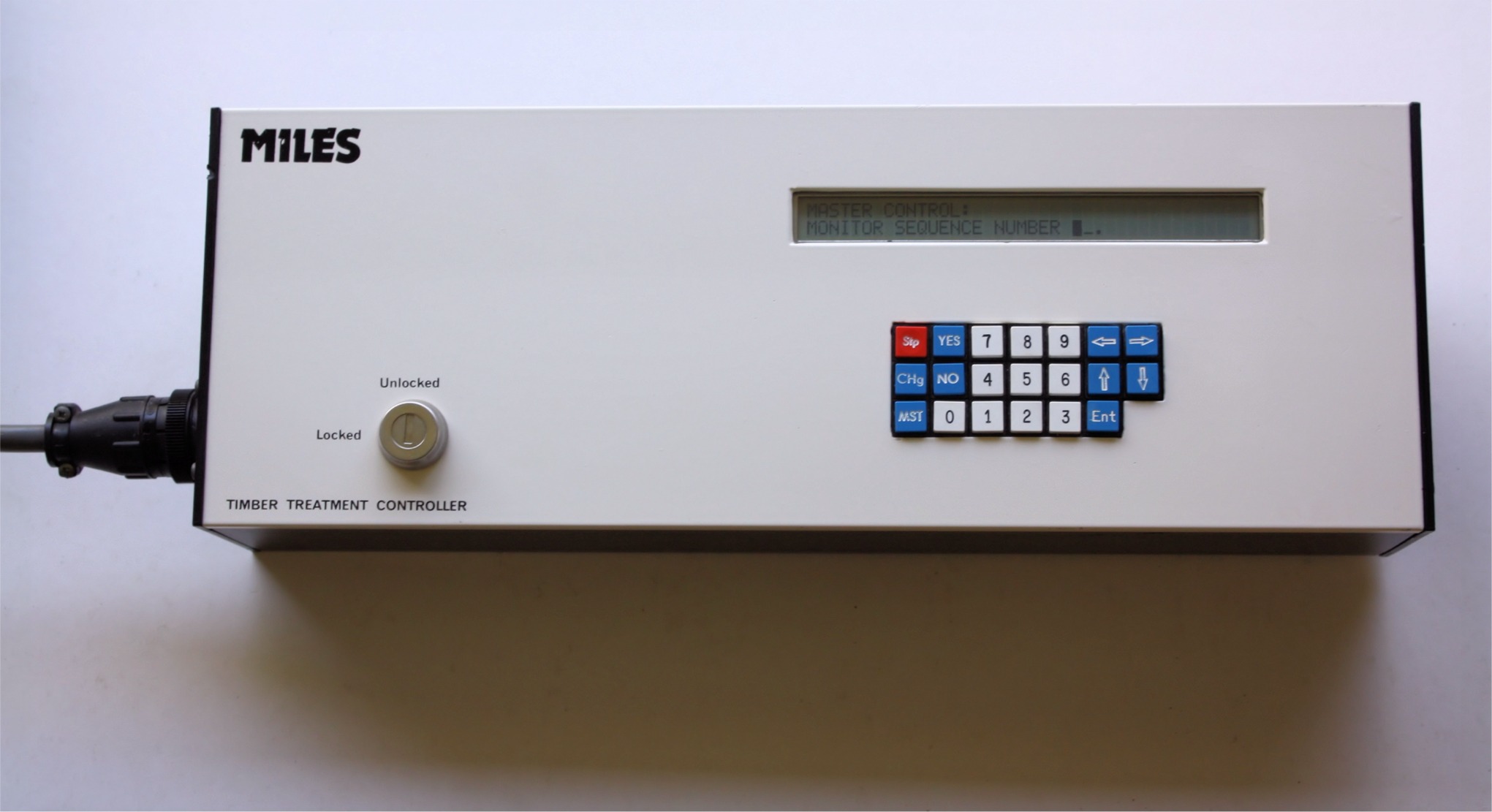

This controller provided total automation of a timber pressure treatment plant which preserved timber by impregnating it with the salts of copper, chrome and arsenic (CCA). Based on the same hardware as the Energy Management System, the basic design of this controller was also marketable as a general purpose control system suitable for a wide range of sophisticated industrial control applications.

As a timber treatment controller, this equipment was designed to allow for the remote or centralised control of all necessary pumps and valves to provide for the automated control of Hickson's "Tanalith CCA" timber treatment plants. To be able to design and test this controller it was necessary for me to be fully familiar with the theory and operation of the process. I was fully trained as an operator and often left in sole charge of the plant at Tuakau for this purpose. I wrote the operating system and all the control logic code using Motorola 6800 Micro-Assembler.

In 1983 when this was designed (before programmable logic controllers were developed), it was considered radically new and exciting. Even today it would not be out of place in a similar situation.

The following is a letter of recommendation from M Sutton of Hicksons Timber Impregnation Co.;