Accurate information obtained directly from the factory benefits all aspects of management and process control, including purchasing, production planning, factory supervision, sales and accounting. This system was an early and very successful attempt to automate specific manufacturing business processes and monitoring not just the rate of production, but the reasons for and period of down-time.

The product was comprised of a distributed network of up to 100 devices linked together to provide individual machine performance monitoring, whilst concentrating information for management purposes at a centralised IBM PC. This provided accurate information directly from the factory to the office, allowing improved production planning, factory supervision, and inventory management as well as more timely accounting.

Each device had two independently operating microcomputers inside – one to do the monitoring and control functions, and the other to provide keyboard, screen and communications functions. I wrote all production monitor code using Motorola 6800 Micro-Assembler. The PC application code was sub-contracted to developers using Pascal, but I wrote the PC communications and data management code using Microsoft 8080 Macro-Assembler, hosted on IBM DOS 2.0.

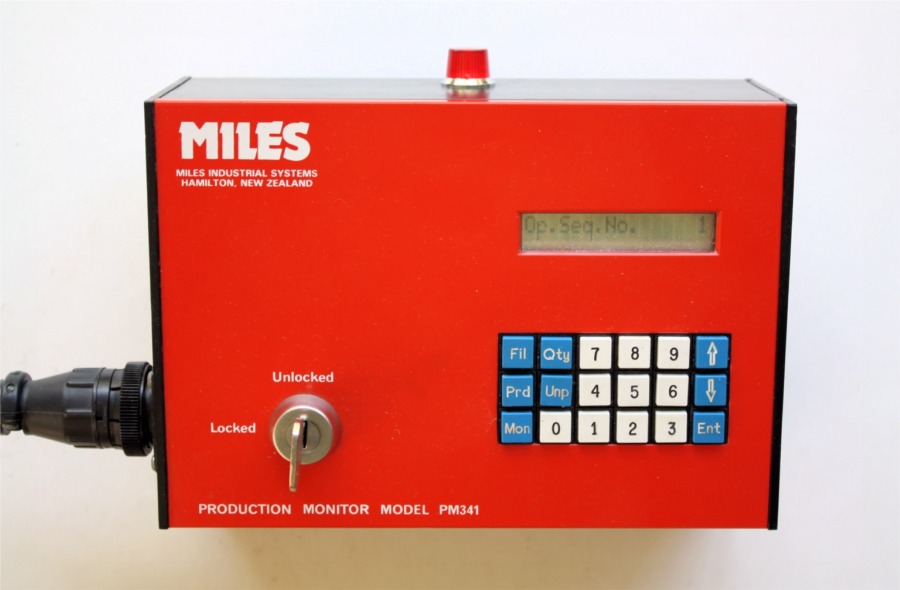

The monitors were coloured bright red as the environment they were designed for was quite drab, with most colours being combinations of grey and green. This was more successful than I had expected, as the operators appreciated the concept and carefully kept them clean despite being in some very dirty areas.

Miles Industrial Systems - Production Monitor PM341

Original Brochure