This product was developed to provide consumers of electrical energy with the ability to contain energy costs within pre-defined practical limits. It enabled the automated control of energy usage required to maintain environmental conditions (for air conditioning and lighting) and production processes. It combined the advantages of time-switching and load-shedding controls in an easy to install and operate package. Substantial savings were obtained (with a six-week pay-back at Todd / Mitsubishi Motors in Porirua) through the redistribution of load and reduction in wasted energy.

The system provided independent control of up to 500 loads to achieve a single integrated power management objective. The programming incorporated the ability to “learn” from experience (e.g. how much effect “losing” any particular load has, allowing load prediction), which made programming simpler than would otherwise have been required. The large number of loads controlled was made possible by transmitting all controls over a network supported by a single 3-core electrical cable. This made installation easier for electricians in the 1980s and at one hospital meant that an existing disused cable in an underground conduit could be used. I wrote the operating system and all the energy management code using Motorola 6800 Micro-Assembler, which was barely better than writing in hexadecimal machine code.

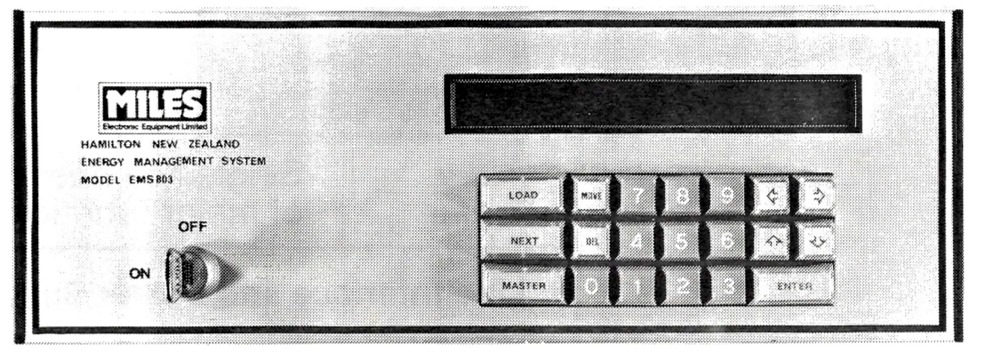

Further detail can be seen in the original promo sheets we produced for the product;

The following is a letter of recommendation from Des Hill at Ajax Fasteners;